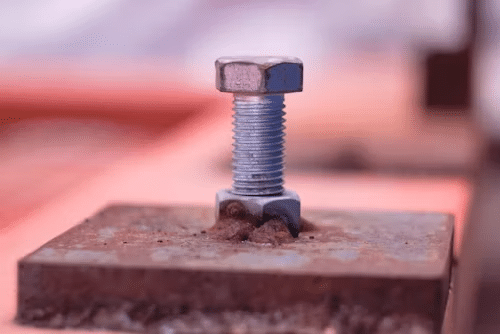

When it comes to construction and building projects, ensuring that everything is properly secured is critical. One of the most reliable and durable fastening options for concrete and masonry is stainless steel wedge anchors. These anchors are designed to expand and grip tightly to the base material, providing a secure hold that can withstand heavy loads and extreme conditions.

At Fastening Specialists, we understand that choosing the right fastening solution can be overwhelming. With so many options available, it can be difficult to determine which one is the best fit for your specific application. That’s where we come in. As a trusted wholesale distributor for over 65 years, we are specialists in the field of fastenings. We offer a wide range of stainless steel wedge anchors in various sizes and materials to meet the needs of any project.

Our team of experts is dedicated to providing you with the best in product value, insight, and code expertise. We work closely with our customers to ensure that they have the right fastening solution for their specific application. Whether you’re working on a small DIY project or a large-scale construction project, you can trust us for all of your fastening needs.

Understanding Wedge Anchors

If you’re looking for a fastener that can provide a strong and reliable connection, wedge anchors are a great option. These fasteners are designed to work with various base materials, including normal-weight concrete, lightweight concrete, and solid masonry, making them versatile and suitable for a range of applications.

Types and Materials

Wedge anchors come in various types, each designed to meet specific application requirements. Stainless steel wedge anchors, for example, offer excellent corrosion resistance, making them ideal for use in harsh environments or applications where exposure to moisture is a concern. 304 stainless steel is a common choice for general-purpose applications, while 316 stainless steel is a more corrosion-resistant option.

Carbon steel wedge anchors, on the other hand, are a cost-effective option that offer good strength and durability. They are typically zinc-plated to provide some corrosion resistance, but are not recommended for use in outdoor or corrosive environments.

Mechanical Properties

Wedge anchors work by expanding the metal when a screw is inserted, effectively wedging the anchor in place. The amount of expansion and the resulting holding strength depend on the size and type of anchor, as well as the base material.

When selecting a wedge anchor, it’s important to consider the expected load requirements of the application. Steel and stainless steel wedge anchors typically offer higher load capacities compared to zinc-plated anchors, so choose a material that can handle the expected load requirements of the application.

Design and Technical Data

Stainless steel wedge anchors are a popular choice for fastening applications in concrete and masonry due to their high strength and corrosion resistance. When selecting a wedge anchor, it is important to consider the specifications and codes that apply to your specific application, as well as the load capacity and performance of the anchor.

Specifications and Codes

Stainless steel wedge anchors are typically tested and evaluated according to industry standards such as ICC-ES Report AC193. This report provides technical data and test results for various sizes and types of wedge anchors, including stainless steel models.

In addition to ICC-ES Report AC193, it is important to consider the specific codes and regulations that apply to your application. For example, seismic design categories A through F require specific testing and evaluation of fastening systems to ensure that they can withstand seismic activity.

Load Capacity and Performance

Stainless steel wedge anchors are designed to provide high load capacity and performance in concrete and masonry. The ultimate tension and shear values for these anchors depend on a variety of factors, including the diameter and length of the anchor, the depth of embedment, and the type of concrete or masonry being used.

When selecting a stainless steel wedge anchor, it is important to choose an anchor that is appropriate for the load and performance requirements of your specific application. The load capacity and performance of each anchor can be found in the technical data provided by the manufacturer.

Installation Process

Preparation and Tools

Before installing stainless steel wedge anchors, it is important to gather all the necessary tools and equipment. A hammer drill, a drill bit, an impact wrench, a torque wrench, a nut, and a washer are required for the installation process.

We are the best option for all your fastening needs. With over 65 years of experience as a trusted wholesale distributor, we are specialists in this field. We offer a wide range of fasteners, including stainless steel wedge anchors, and our team of experts can help you choose the best product for your specific application.

Step-by-Step Guide

- Begin by selecting the appropriate drill bit for the size of the wedge anchor being used. The diameter of the hole should be slightly larger than the diameter of the anchor to allow for easy installation.

- Drill a hole into the concrete surface to the required depth and diameter specified for the wedge anchor being used. It is important to clean the hole to remove debris or dust using a wire brush or vacuum.

- Insert the wedge anchor into the hole, making sure it is flush with the surface of the concrete.

- Place the washer and nut onto the threaded end of the wedge anchor.

- Using an impact wrench, tighten the nut until it is snug against the washer.

- Use a torque wrench to tighten the nut to the recommended installation torque specified for the wedge anchor being used.

- Verify that the wedge anchor is fully seated and secure by applying pressure to the nut and washer.

We offer a wide range of stainless steel wedge anchors that are suitable for a variety of applications. Our team of experts can help you choose the best product for your specific needs, and we offer fast, reliable order fulfillment. Trust the specialists for all your fastening needs.

Applications and Use Cases

Industrial and Construction

Stainless steel wedge anchors are a popular choice for industrial and construction applications due to their strength and durability. They can be used to fasten structural steel, handrails, and other heavy equipment to both cracked and uncracked concrete surfaces. The dual undercutting embossments on each clip segment of some wedge anchors, like the Strong-Bolt® 2 Wedge Anchor, enable secondary expansion should a crack form, providing a secure fastening solution even in seismic and high-wind conditions.

Home Anchoring Systems

Stainless steel wedge anchors are also a great option for home anchoring systems. They can be used to secure heavy items such as shelves, cabinets, and TVs to concrete walls. Type 316 stainless steel anchors are resistant to rust and corrosion, making them ideal for use in outdoor or marine environments.

Fastening Specialists offers a variety of stainless steel wedge anchors in different sizes, designs, and coatings to meet your specific needs. Our extensive product range and expertise in the field of fastening make us the best choice for all your anchoring needs. Trust the specialists for the best in product value, insight, and order fulfillment.

Maintenance and Longevity

Stainless steel wedge anchors are known for their low maintenance requirements and longevity. Due to their excellent corrosion resistance properties, they are highly resistant to rust and other forms of corrosion. This makes them an ideal choice for outdoor and highly corrosive environments.

To ensure the longevity of your stainless steel wedge anchors, it is important to implement a maintenance schedule and promptly address any concerns. This will help prolong the lifespan of the anchors and contribute to long-term structural stability.

When it comes to seismic and high-performance applications, stainless steel wedge anchors are an optimal choice. They are code listed for cracked and uncracked concrete, and masonry applications, making them suitable for even the most demanding conditions.

In summary, stainless steel wedge anchors require minimal maintenance, have excellent corrosion resistance properties, and are highly durable.

The team at fastening specialists provides advice and best use-cases, but always check with local building codes and engineers for correct usage instructions.