When it comes to drilling, having the right drill bit is essential for achieving the desired results. With so many sizes, applications, features, designs, materials, coatings, and SKU names, it can be overwhelming to decide what drill bits you need. In this article, we will provide you with a comprehensive guide on what drill bits you need for your projects.

Whether you are a DIY enthusiast or a professional contractor, having the right drill bit is critical to achieving your desired results. In the next section, we will take a closer look at the different types of drill bits available and their specific uses.

Understanding Drill Bits

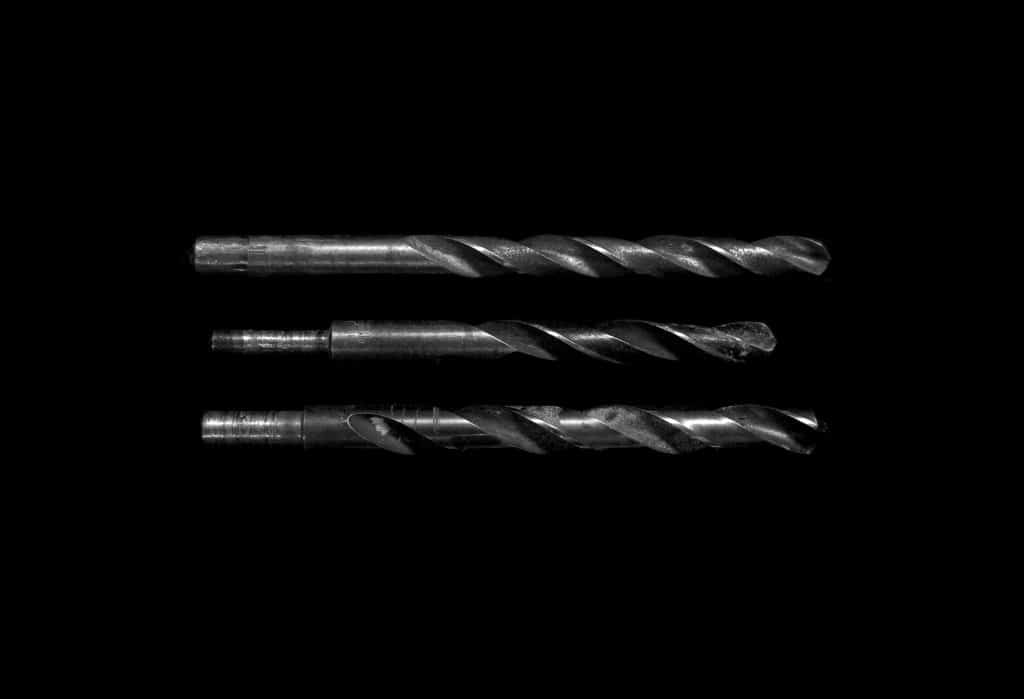

Drill bits are essential tools for anyone who needs to make holes in different materials. They come in a variety of shapes, sizes, and materials, each designed for specific applications. In this section, we will explore the different types of drill bits and the materials and coatings used to make them.

Types of Drill Bits

There are many types of drill bits, including twist drill bits, step drill bits, forstner bits, hole saws, masonry drill bits, auger bits, spade bits, and cobalt drill bits. Each type of drill bit is designed for specific applications, such as drilling through wood, metal, concrete, or other materials.

- Twist drill bits are the most common type of drill bit and are suitable for drilling through most materials. They have a spiral shape and come in a range of sizes.

- Step drill bits are designed for drilling holes of different sizes in one go. They are great for drilling through thin materials like sheet metal.

- Forstner bits are ideal for drilling flat-bottomed holes in wood. They are great for creating holes for dowels or other decorative features.

- Hole saws are used for cutting large holes in wood, metal, or plastic. They are great for installing pipes or cables.

- Masonry drill bits are designed for drilling through brick, concrete, or other masonry materials. They have a carbide tip that can withstand the hard surface of the material.

- Auger bits are designed for drilling deep holes in wood. They have a screw-like shape that pulls the bit through the wood as it spins.

- Spade bits are designed for drilling large holes in wood. They have a flat, paddle-like shape that cuts through the wood quickly.

- Cobalt drill bits are made of high-speed steel with added cobalt. They are designed for drilling through hard metals like stainless steel.

Materials and Coatings

Drill bits are made from a variety of materials, including high-speed steel, titanium, carbide, and cobalt. Each material has its own strengths and weaknesses.

- High-speed steel is the most common material used for drill bits. It is affordable and can be used for drilling through most materials.

- Titanium-coated drill bits are more durable than high-speed steel bits. The coating helps to reduce friction and heat buildup, which can extend the life of the bit.

- Carbide drill bits are made of a hard, brittle material that is ideal for drilling through hard materials like concrete or tile.

- Cobalt drill bits are made of high-speed steel with added cobalt. They are more durable than regular high-speed steel bits and can withstand higher temperatures.

Selecting the Right Drill Bit for the Material

When it comes to selecting the right drill bit for the job, the material you are drilling into is a crucial factor. Different materials require different types of drill bits to ensure a clean and accurate hole. Here are some of the most common materials and the drill bits that are best suited for them:

Wood Drill Bits

When drilling into wood, the best type of drill bit to use is a twist bit. These are the most common type of drill bit and are suitable for drilling into most types of wood. For larger holes, a spade bit or hole saw may be more appropriate.

Metal Drill Bits

When drilling into metal, it is important to use a drill bit that is designed specifically for the type of metal you are working with. For softer metals like aluminum, brass, and copper, a high-speed steel (HSS) drill bit is a good choice. For harder metals like steel and cast iron, a cobalt drill bit is recommended.

Masonry Drill Bits

When drilling into masonry materials like concrete, brick, or stone, a masonry drill bit is required. These drill bits have a carbide tip that is designed to handle the hardness of these materials. It is important to use a hammer drill when drilling into masonry to ensure that the drill bit can penetrate the material.

Specialized Drill Bits

For specialized materials like fiberglass, porcelain, and tiles, there are specific drill bits designed for these materials. For example, a diamond-tipped drill bit is recommended for drilling into glass, while a tile drill bit is designed for drilling into ceramic tiles.

Overall, selecting the right drill bit for the material is crucial for achieving accurate and clean holes. At Fastening Specialists, we have over 65 years of experience as a trusted wholesale distributor of fastenings. We are specialists in this field and can provide you with the best product value, insight, and code expertise for all your fastening needs. Remember to always check with local building codes and engineers for correct usage instructions.

Drill Bit Anatomy and Attachments

When it comes to drill bits, it’s important to understand their anatomy and attachments to ensure you’re using the right tool for the job. There are many different types of drill bits available, each with its own unique features and functions. In this section, we’ll discuss the anatomy of drill bits and the different attachments available.

Understanding Bit Tips and Points

One of the most important aspects of a drill bit is the tip or point. The tip is the part of the bit that actually cuts into the material you’re drilling. There are several different types of tips available, each designed for specific materials and applications.

- Twist Bits: These are the most common type of drill bit and are designed for drilling into wood, metal, and plastic. They have a sharp, pointed tip that allows them to cut through the material.

- Brad-Point Bits: These are similar to twist bits but have a center point that helps keep the bit on track. They’re ideal for drilling into wood.

- Auger Drill Bit: These bits have a screw-like design that helps pull the bit through the material as you drill. They’re ideal for drilling into thick wood or other dense materials.

- Forstner Drill Bit: These bits are designed for drilling flat-bottomed holes and are ideal for woodworking projects.

- Spade Drill Bit: Also known as paddle bits, these have a flat, paddle-shaped tip that’s ideal for drilling larger holes in wood.

Shank Types and Chuck Compatibility

The shank is the part of the bit that fits into the drill’s chuck. There are several different types of shanks available, each designed for specific types of drills.

- Hexagonal Shank: These shanks have six sides and are designed for use with impact drivers and other hexagonal chuck tools.

- Round Shank: These shanks are the most common and are designed for use with most standard drill chucks.

- SDS Shank: These shanks are designed for use with SDS drills and are ideal for heavy-duty applications.

When choosing a drill bit, it’s important to ensure that the shank is compatible with your drill’s chuck. Using the wrong type of shank can result in poor performance and even damage to your drill.

Practical Applications of Drill Bits

Drill bits are essential tools for any DIY project, woodworking, or building tasks. They come in a variety of sizes, materials, and shapes to cater to different uses and tasks. In this section, we will explore some of the common tasks and projects that require drill bits and the professional use cases.

Common Tasks and Projects

Woodworking and Furniture

If you are into woodworking or furniture building, you will need drill bits to create holes for dowels, screws, and bolts. For this purpose, you can use brad point bits, spade bits, or Forstner bits. Brad point bits are ideal for creating clean and precise holes, while spade bits are best for creating larger holes in softwood. Forstner bits are perfect for creating flat-bottomed holes in hardwood.

Renovation

Renovation projects often require drilling into walls, ceilings, and floors to install fixtures, hang pictures, or run electrical wires. For this purpose, you can use masonry bits, twist bits, or auger bits. Masonry bits are designed to drill into concrete, brick, and stone, while twist bits are ideal for drilling into wood, plastic, and metal. Auger bits are best for drilling deep holes in wood.

Professional Use Cases

Electricians and Plumbers

Electricians and plumbers often need to drill holes in walls, floors, and ceilings to install wiring, pipes, and fixtures. For this purpose, they use hammer drills and rotary hammers with masonry bits to drill into concrete and brick.

Joinery

Joinery requires precision and accuracy when drilling holes for dowels, screws, and bolts. For this purpose, joiners use brad point bits, Forstner bits, and spade bits to create clean and precise holes.

Maintenance and Safety Tips

Proper Drill Bit Care

Maintaining your drill bits is crucial to ensure their longevity and precision. Regular cleaning and sharpening of your drill bits will help prevent damage and prolong their lifespan. It is also important to inspect your drill bits before use to ensure they are in good condition.

To clean your drill bits, use a soft cloth to wipe away any debris or buildup. You can also use a bit cleaner to remove any stubborn buildup. When sharpening your drill bits, make sure to use a sharpening stone or file designed for drill bits. Avoid using a grinding wheel, as this can damage the bit.

Proper storage of your drill bits is also important. Keep them in a dry, clean place to prevent rust or damage. Consider using a drill bit case or organizer to keep your bits organized and easily accessible.

Safety Considerations During Use

When using your drill, it is important to prioritize safety. Always wear appropriate safety gear, including eye protection and earplugs. If using a drill press, make sure it is securely mounted and the workpiece is clamped down.

When drilling, start at a slow speed to ensure accuracy and precision. Apply steady pressure to the drill, but avoid pushing too hard to prevent damage to the bit or workpiece. If you encounter any resistance, stop drilling immediately and inspect the bit and workpiece for damage.

Remember, the team at Fastening Specialists provides advice and best use-cases, but always check with local building codes and engineers for correct usage instructions.